Looking for quality-built commercial trash compactors you can count on? You’ve found ’em.

Our 2 cubic yard self-contained compactors are the ideal waste management solution for the hospitality, retail, and healthcare industries.

Not only do they feature exceptional design and materials to maximize longevity, they will reduce garbage hauling costs, help maintain a clean workplace, and cut offensive odors. As for usability? They’re a snap to operate.

Our 2 yard self-contained commercial trash compactors are quality-built:

- 1/2" steel AR plate floor with 3" structural channels

- 1/4" steel plate sides with 4" x 2" x 1/4" and 6" x 2" x 1/4" structural steel tubing with 6" channel

- Breaker bar 6" x 6" x 1/2" hydraulic cylinder mounts

- Replaceable 1/2" UHMW polyethylene wear bars on ram sides, tops and bottoms for a smooth, quiet and near frictionless operation

- Weatherproof control panel and power pack

- Removable rear and top access panels

- Synthetic biodegradable hydraulic oil

- Phosphatize-cleaned, inside and out

Our commercial trash compactors are constructed with quality electrical and hydraulic features:

- Controlled power unit, or PLC

- E-stop button

- Automatic single cycle

- Auto/manual selector

- Key lock on/off switch

- Low oil sensor shutdown

- Multi cycle

- 80%-100% full lights

- Automatic shutdown with auto safety retract

- 15' remote

- Fluid filled pressure gauge

- Inlet fluid strainer

- 15' Hydraulic hoses

- Left or right hydraulic connections

This compactor’s container is constructed from:

- 3/16" steel plate floor with 6" x 2" x 1/4" structural steel tubing rails with 1/2" x 2" steel tubing rails with 1/2" x 2" steel bottom wear bars

- 3/16" steel plate sides, roof and door

- Full 3/4" thick door seal

- Double end pick-up (standard with outside rail cable pull)

- Tapered width from 80" at compactor to 88" at door (inside dimensions)

- Exclusive side and bottom ratchet door and latch system with heavy duty hinges and grease fittings

Details. You want ‘em, you’ve got ‘em.

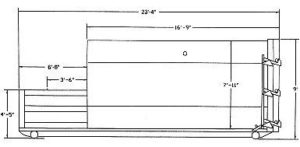

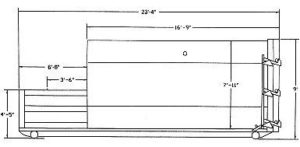

| Model |

NSC-200-35 |

| Length |

23'4" |

| Width |

8'5" |

| Height |

8'6" |

| Loading Height |

4' |

| Approx. Weight |

10,900 lbs |

| Compactor Capacity |

2 cu yd |

| Compactor Floor |

3/8" AR steel plate with 3" structural channels |

| Compactor Sides |

1/4" steel plate sides with 4" x 2" x 1/4" and 6" x 2" x 1/4" structural steel tubing with 6" channel |

| Container Capacity |

35 cu yd |

| Container Floor |

3/16" steel plate with 6" x 2" x 1/4" structural steel tubing rails with 1/2" x 2" steel bottom wear bars |

| Container Sides & Top |

3/16" steel plate |

| Container Width |

Tapered front to rear |

| Full Door Seal |

3/4" thick |

| Ram Face & Bottom |

3/8" AR steel plate |

| Platen Area |

5' x 3'8" x 3' |

| Charge Opening |

3'6" x 5" |

| Ram Penetration |

1' |

| Breaker Bar |

6" x 6" x 1" with retaining teeth |

| Twin Bypass Cylinders |

6" x 6" x 1" with retaining teeth |

| Hydraulic Cylinder Mounts |

6" x 6" x 1/2" |

| Hydraulic Fluid |

Biodegradable |

| Wear Bars |

Replaceable 1/2" UHMW polyethylene |

| Line Pressure |

2,000 psi |

| Max Line Pressure |

2,500 psi |

| Max Ram Force |

63,000 lbs |

| Cycle Time |

45 sec |

| Fluid Capacity |

35 gal |

| Pump |

10-1/2 gpm |

| Motor |

10 hp 3-phase or single phase inverter |

(All measurements are outside dimensions)

Download our Spec Sheet

Want to customize your self-contained compactor? We’re happy to help.

Options include:

- 10 HP 230V, single phase

- Fluid reservoir heater

- Open hopper (for dock or ground loading)

- Enclosed doghouse with door and interlock

- Walk on or drive on deck with 42" safety rails

- Side loading hoppers

- Through-the-wall chutes

- Cart dumper system

- Container guide rails

- Hydraulic tailgate

- Fullness monitoring system

We believe in the compactors we've designed and manufactured. It's why we can confidently offer the industry's best warranty.

Nedland Compactor Warranty